Zinc Dross

Zinc Dross Specification

- Thickness

- Variable

- Condition

- Used

- Zinc Content

- 90-95%

- Alloy

- No

- Purity

- 90-95%

- Scrap Type

- Zinc Dross

- Material

- Zinc

- Density

- 7.14 Gram per cubic centimeter(g/cm3)

- Application

- Galvanizing, Brass Manufacturing, Chemical Industry

- Dimension (L*W*H)

- Variable

- Weight

- 25-50 kg per piece

- Color

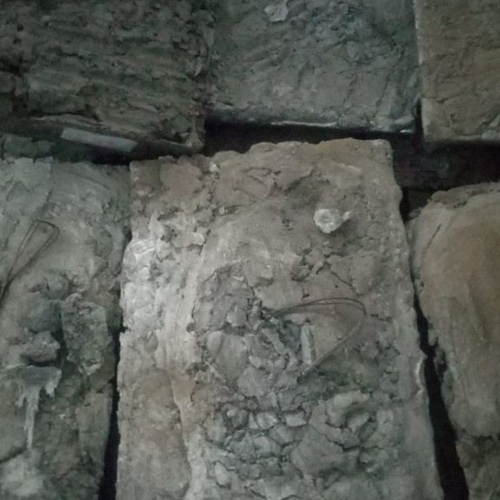

- Greyish White

- Packaging Type

- Loose or Jumbo Bags

- Form

- Solid Lumps

- Impurity Content

- Aluminium, Iron, Minor impurities

- Storage Condition

- Dry Place, Avoid Moisture

- Melting Point

- 419.5°C

Zinc Dross Trade Information

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Australia, South America, Middle East, Western Europe, Central America, Africa, Asia, Eastern Europe, North America

- Main Domestic Market

- All India

About Zinc Dross

Our organization is actively indulged in processing and supplying in the finest quality Zinc Dross. Having rust free nature, purity, high strength and durability, this type dross is great to be used for the manufacture of zinc powder, which is required in metallurgical industry. It is a mass of solid impurities floating on a melted metal or disseminated in the metal, like in wrought iron. The Zinc Dross takes the form on the surface of low-melting-point metals like alloys, zinc, aluminium, tin, and lead by oxidation of the metal.

Versatile Applications in Industry

Zinc Dross covers a broad spectrum of industrial applications. Its high zinc content makes it suitable for the production of brass, recovery of metallic zinc, and specialized uses in the chemical industry. Consistent supply in variable lump sizes and reliable purity levels help meet the demanding requirements of customers ranging from galvanizers to metal manufacturers across Indonesia and beyond.

Quality and Purity Standards

Every batch of Zinc Dross is carefully evaluated to maintain a zinc purity of 90-95%. Minor impurities such as iron and aluminum are present but do not diminish its effectiveness. The material is suitable for processes requiring a trusted source of secondary zinc input and is provided in packaging options like loose stacking or sturdy jumbo bags.

Safe Handling and Storage

To preserve quality and prevent unwanted reactions, Zinc Dross must be stored in a dry environment away from moisture. This minimizes the risk of oxidation or contamination, ensuring the material retains its properties until use. Proper storage also supports safer handling practices and material longevity.

FAQs of Zinc Dross:

Q: How is Zinc Dross typically processed before industrial use?

A: Zinc Dross is usually sorted based on its purity, size, and zinc content. It may be melted to recover zinc metal or incorporated directly into metallurgical processes like brass manufacturing and galvanizing, depending on application requirements.Q: What are the main benefits of using Zinc Dross in manufacturing?

A: Zinc Dross offers cost-efficiency as a secondary zinc source, high metal content (90-95%), and reliable performance in galvanizing or alloy production. It allows for the recovery and recycling of zinc, reducing waste and saving resources in industrial operations.Q: When should Zinc Dross be used instead of pure zinc?

A: Zinc Dross is ideal for processes where ultra-high purity zinc is not essential. It is commonly utilized in applications such as galvanizing or producing brass alloys, where its minor impurities do not negatively impact the final product quality.Q: Where should Zinc Dross be stored to maintain quality?

A: Zinc Dross must be kept in a dry place and protected from moisture. Proper storage in indoor facilities or sealed bags helps prevent oxidation, ensuring the material remains suitable for further processing or resale.Q: What is the typical usage form and packaging available for Zinc Dross?

A: Zinc Dross is supplied as solid greyish white lumps of variable dimensions and thickness, usually weighing 25-50 kg each. It is packaged either as loose pieces or in robust jumbo bags, depending on client preference or logistical needs.Q: How does the impurity content affect the suitability of Zinc Dross for various applications?

A: While Zinc Dross contains minor amounts of aluminum and iron, its high zinc purity (90-95%) makes it suitable for most metallurgical and industrial applications. The impurities are well-tolerated in processes like brass and chemical manufacturing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Zinc Scrap Category

Zinc Scrap

Color : Grey

Purity : 99% 99.99%

Dimension (L*W*H) : As per requirement

Alloy : Zamak / Other Zinc Alloys

Weight : Available in bulk or as per buyers need

Application : Galvanizing, Alloy Production, Die Casting, Chemical Industry, Metal Recovery

Lead Ash

Color : Grayish Black

Purity : 5565%

Dimension (L*W*H) : Variable

Alloy : Lead Alloy

Weight : Per customer requirement

Application : Battery manufacturing, Metal recovery, Recycling industry

Zinc Ingot

Color : Silver Grey

Purity : 99.99%

Dimension (L*W*H) : As per order/specification

Alloy : NonAlloy

Weight : Approximately 25 kg/ingot

Application : Galvanizing, Die Casting, Chemical Industry, Electroplating, Alloy Manufacturing

|

PT. SINAR LAUT BIRU LOGAM PERKASA JAYA

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry